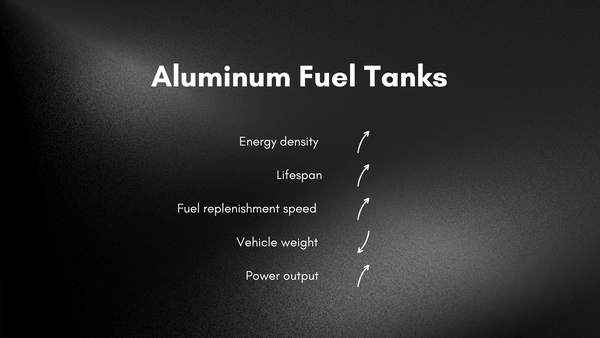

The automotive industry is constantly evolving and seeking innovative technologies to improve vehicle performance and efficiency. One promising technology is the use of aluminum fuel cells as an alternative to traditional lead-acid or lithium-ion batteries. Aluminum fuel cells offer several advantages over traditional batteries, including higher energy density, longer lifespan, faster-recharging ability, and lower overall cost. They have the potential to revolutionize efficiency in the automotive industry by enabling faster refueling times, lower vehicle weight, and higher electrical output to power more vehicle features. Aluminum fuel cells work by oxidizing the aluminum plates within the cell which releases electrons that create electrical current. When paired with proper fueling technology, aluminum fuel cells could enable electric vehicles to refuel as quickly as gasoline vehicles.

What are Aluminum Fuel Cells?

Aluminum fuel cells, also known as aluminum-air batteries, are an emerging battery technology that uses aluminum as the anode and oxygen from the air as the cathode. They operate on a similar principle to traditional fuel cells, using an ion-conducting medium such as an electrolyte to pass charged ions between the anode and cathode and create an electrical current. When aluminum reacts with oxygen and water in the electrolyte, it generates electrons which create an electrical potential that can be harnessed as electric power. Aluminum fuel cells have several advantages over traditional batteries:

- Higher energy density. Aluminum has high specific energy at 8,000 Wh/kg compared to 200~300 Wh/kg for lead-acid batteries and 250 Wh/kg for lithium-ion batteries. This means aluminum fuel cells can store more energy per unit weight, making them ideal for electric vehicle applications.

- Longer lifespan. Unlike lithium-ion batteries that degrade over charging cycles, aluminum fuel cells can theoretically last indefinitely as long as they are properly refueled with aluminum and electrolyte.

- Rapid refueling. Aluminum fuel cells can be recharged quickly by replacing the oxidized aluminum plates, potentially allowing electric vehicles to refuel as fast as gasoline vehicles.

Benefits of Aluminum Fuel Cells in the Automotive Industry

The benefits of aluminum fuel cells for the automotive industry are significant and have the potential to revolutionize vehicle efficiency. Some of the key advantages include:

- Lower vehicle weight. Due to their high energy density, aluminum fuel cells could substantially reduce vehicle battery weight compared to current lithium-ion systems. This extra weight savings could improve vehicle performance, handling, and efficiency.

- Increased electrical output. Aluminum fuel cells provide more electrical current, allowing electric vehicles to power more electrical features like air conditioning, heating, infotainment systems, and additional motors to assist acceleration.

- Faster refueling. If aluminum fuel cell technology advances to enable refueling as quickly as liquid fueling, it could significantly improve the usability of electric vehicles by allowing drivers to recharge in just a few minutes compared to hours with current charging methods. This would make electric vehicles more practical for longer trips and commercial applications.

- Lower overall costs. Over time, aluminum fuel cells are expected to become cheaper than lithium-ion batteries due to the higher abundance and lower cost of raw materials. These cost savings could trickle down to lower electric vehicle prices.

In summary, aluminum fuel cells have the potential to revolutionize the automotive industry by enabling lighter, longer-range, faster-refueling electric vehicles that are more practical and affordable for everyday use.

Challenges and Limitations of Aluminum Fuel Cells

While aluminum fuel cells offer many advantages over traditional batteries, several challenges and limitations must be overcome for widespread automotive usage:

One major issue is the aluminum fuel cell lifespan. Current prototypes have only demonstrated around 500 charge/discharge cycles before losing performance. This is significantly less than the 1,000 to 2,000 cycles for lithium-ion batteries. Researchers are working to improve the electrolytes, membranes, and cell designs to extend aluminum fuel cell lifespan.

Another challenge is refueling speed. Current aluminum fuel cell designs take around 30 minutes to recharge, which is still longer than the 3 to 5 minutes needed for practical consumer use. Researchers are trying to develop more advanced electrolytes and reactors to enable faster refueling.

Cost is also currently prohibitive for mass production. Aluminum fuel cells use expensive components like selectively permeable membranes and metal hydrides to store hydrogen for refueling. Mass production techniques could help reduce costs over time.

Safety concerns also exist due to the combustible and corrosive nature of the electrolytes and chemicals used in aluminum fuel cells. Strict safety standards would need to be developed and implemented for automotive and consumer use.

In conclusion, while aluminum fuel cells show promise for revolutionizing vehicle efficiency, many technological challenges and limitations must still be overcome related to lifespan, refueling speed, costs, and safety before the technology becomes practical for widespread automotive and consumer adoption.

Applications of Aluminum Fuel Cells in the Automotive Industry

Despite the challenges, aluminum fuel cells still hold promise for a variety of applications in the automotive industry:

- Electric vehicles: Aluminum fuel cells could enable lighter, longer-range electric vehicles that recharge considerably faster than current lithium-ion battery designs. They are potentially ideal for powering next-generation EVs.

- Buses and commercial vehicles: The high energy density and faster refueling capabilities of aluminum fuel cells make them well-suited to power electric buses and commercial vehicles that require long range and operate on fixed schedules. This could significantly reduce emissions from these vehicles.

- Military vehicles: Aluminum fuel cells could provide improved power sources for military vehicles and equipment due to their high energy density, long lifespan, and ability to operate under extreme temperatures. They may eventually replace diesel generators for powering military bases.

- Performance vehicles: High-end electric sports cars and performance vehicles could benefit from the lighter weight, higher power output, and faster refueling times enabled by aluminum fuel cells. However, these applications would likely come at a premium cost.

In the longer term, advancements in aluminum fuel cell technology have the potential to transform the entire automotive industry by enabling electric vehicles that are comparable to gasoline vehicles in terms of range, refueling speed, and total cost of ownership. While there are obstacles to overcome, the advantages of aluminum fuel cells make them a promising candidate for powering the next generation of automobiles.

Conclusion

In conclusion, aluminum fuel cells have the potential to revolutionize efficiency and sustainability in the automotive industry. Their high energy density, long lifespan, fast recharging, and lower projected costs compared to lithium-ion batteries could enable electric vehicles that are comparable to gasoline vehicles in the range, refueling speed, and affordability. However, major technological advancements are still needed to be related to fuel cell lifespan, refueling speed, costs, and safety before aluminum fuel cells become practical for widespread automotive usage. If these challenges can be overcome through research and development, aluminum fuel cells could find applications in a variety of automotive sectors from electric vehicles to commercial fleets to specialized military and performance vehicles. While lithium-ion batteries will likely remain dominant for the near future, aluminum fuel cells represent a promising alternative technology that could eventually transform the automotive landscape by enabling greater vehicle efficiency, sustainability, and electrification. Considerable investment and innovation will be required to realize the full potential of aluminum fuel cells, but the rewards could be significant for automakers, consumers, and the environment.

Read More

- Upgrade Your Truck Headlights: The Ultimate Guide for 2023 – Labworkauto

- 5 Steps to Install a Custom Grill on Your Car – Labworkauto

- Mercedes-Benz E260 Sedan Engine Stalls Troubleshooting Guide – Labworkauto

- Fuel Tank Replacement: When to Replace and How? – Labworkauto

- Tips for Choosing a Spare Fuel Tank for Your Long-Distance Self-Driving Tour – Labworkauto